Infrastucture

Infrastucture

Our Machineries

HEIDELBERG SPEED MASTER CD 102

2 Colour (28" x 40")

The Speed Master CD 102 is a highly versatile straight-printing press designed for commercial packaging and printing. Equipped with cutting-edge technology, it enables flexible processing of a wide variety of jobs and materials with minimal effort.

With short make-ready times and seamless integration into the print workflow, the Speed Master CD 102 consistently delivers high print quality at speeds of up to 10,000 sheets per hour.

Its attractive price-to-performance ratio is further enhanced by its capability to produce specialized packaging in up to 6 colours with UV coating applications — making it a reliable asset for high-volume, high-precision print operations.

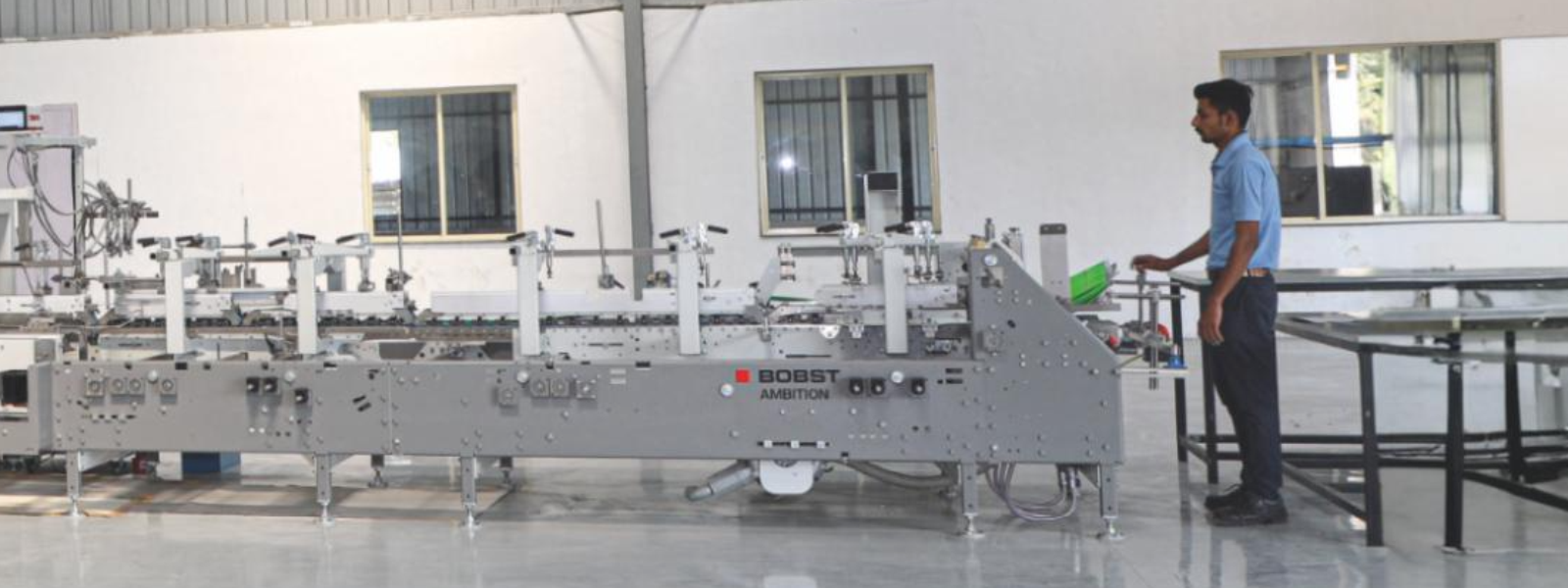

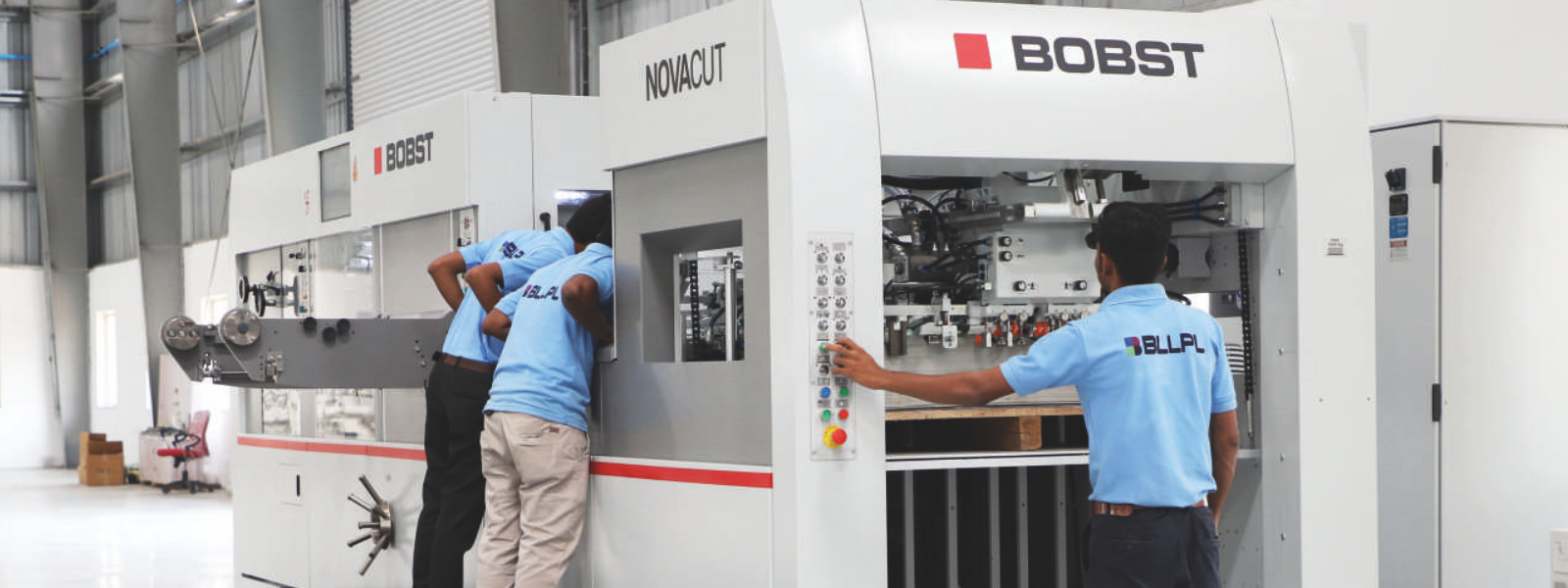

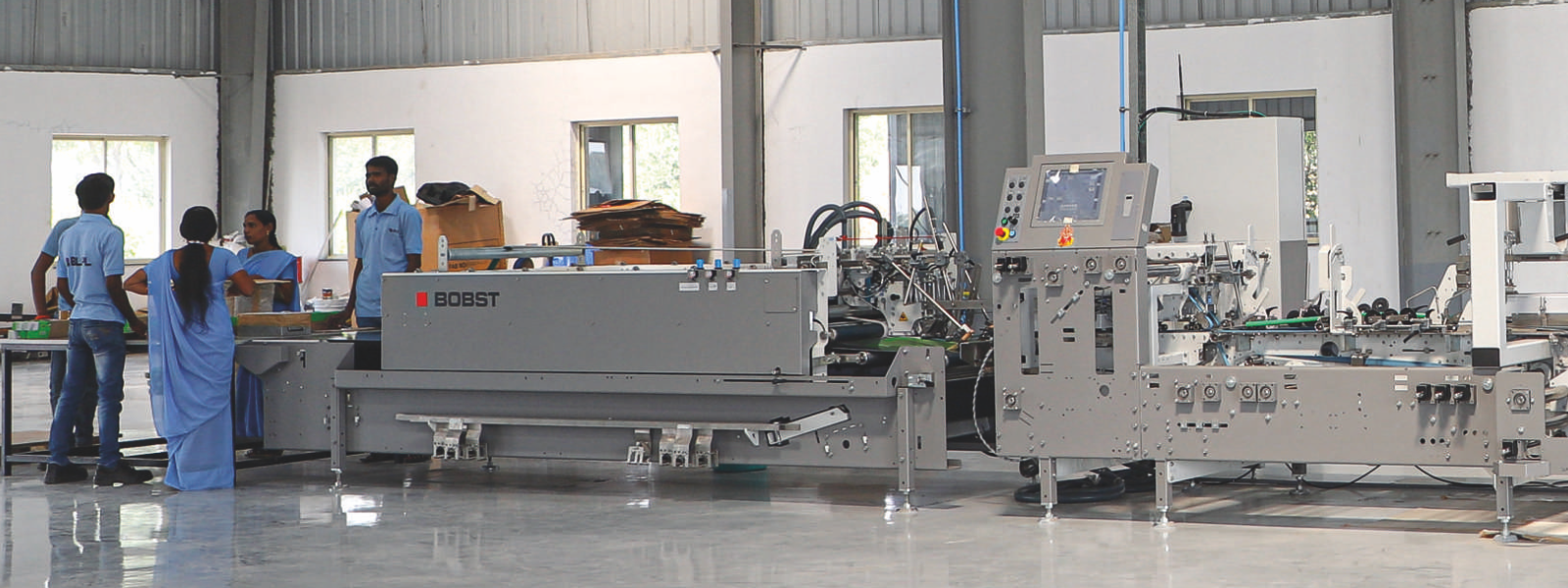

BOBST NOVACUT 106 E

Autoplaten® Die-Cutter

Having the right equipment to get the job done is critical — and NOVACUT 106 E delivers on all fronts.

While increased die-cutter versatility often comes at the cost of productivity, NOVACUT 106 E stands out by offering both—exceptional flexibility and high performance—thanks to its world-leading Autoplaten® technology.

Double Profile Paper Corrugation Machine

With E & F Flute (42")

Engineered for efficiency and versatility, this double-profile corrugation machine supports E and F flute configurations on a 42-inch width, enabling high-quality corrugated sheet production for diverse packaging needs.

Leaflet Folding Machine

Designed for precision and efficiency, this machine enables accurate folding of leaflets and printed inserts — ideal for pharmaceutical, FMCG, and promotional applications.

BOPP Lamination Machine – 28" x 40"

This high-performance lamination machine supports BOPP film application on printed sheets up to 28" x 40", enhancing durability, finish, and shelf appeal of packaging materials.

Manual Punching Machine – 28" x 40"

Engineered for robust manual operation, this machine delivers reliable die-cutting and punching for packaging boards and sheets of various grades and formats.

Fingerless Corrugation Plant

Our Equipment

To ensure the highest quality standards, we employ industry-grade equipment across all stages of production and packaging validation

Rub Scuff Tester

Evaluates abrasion resistance of printed materials.

Weighing Balance

For accurate material and sample measurements.

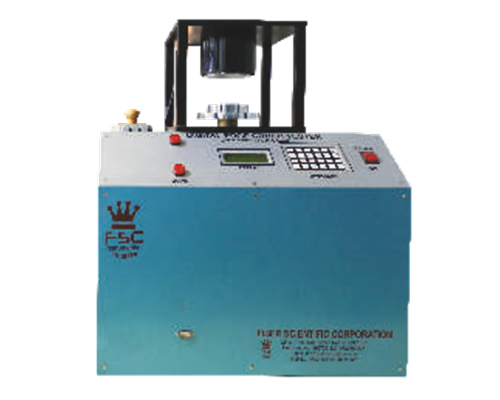

Digital Box Compression Tester

Tests box strength under vertical load.

Industrial Oven

For controlled heating and drying processes.

Digital Edge Crush Tester

Measures the crushing strength of corrugated board edges.

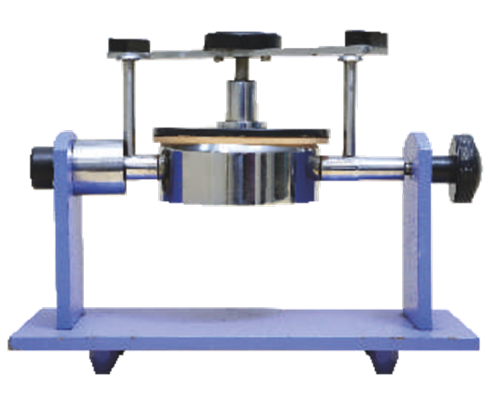

Cobb Value Tester

Assesses water absorption of paper and board.

Ink Kitchen Kit

Facilitates precise ink preparation and testing.

B4 Cup Viscosity Tester

Measures ink and liquid viscosity.

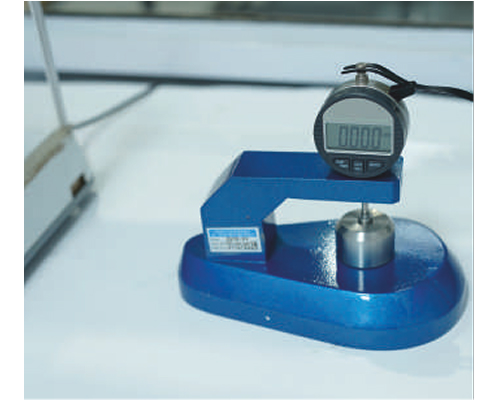

Caliper Gauge Thickness Tester

Ensures uniform material thickness.

Moisture Meter

Checks moisture content in packaging substrates.

Bursting Strength Tester

Evaluates the bursting resistance of paper/board.

Hot Air Treatment Plant

Provides uniform heat treatment for packaging components.